Pellet Production Plant

With the world moving toward cleaner, renewable energy, biomass pellets are becoming one of the most sustainable and cost-effective alternatives to fossil fuels.

We help businesses turn agricultural, forestry, and industrial waste into valuable biofuel - reducing emissions, increasing efficiency, and boosting profitability.

Explore our solutions >

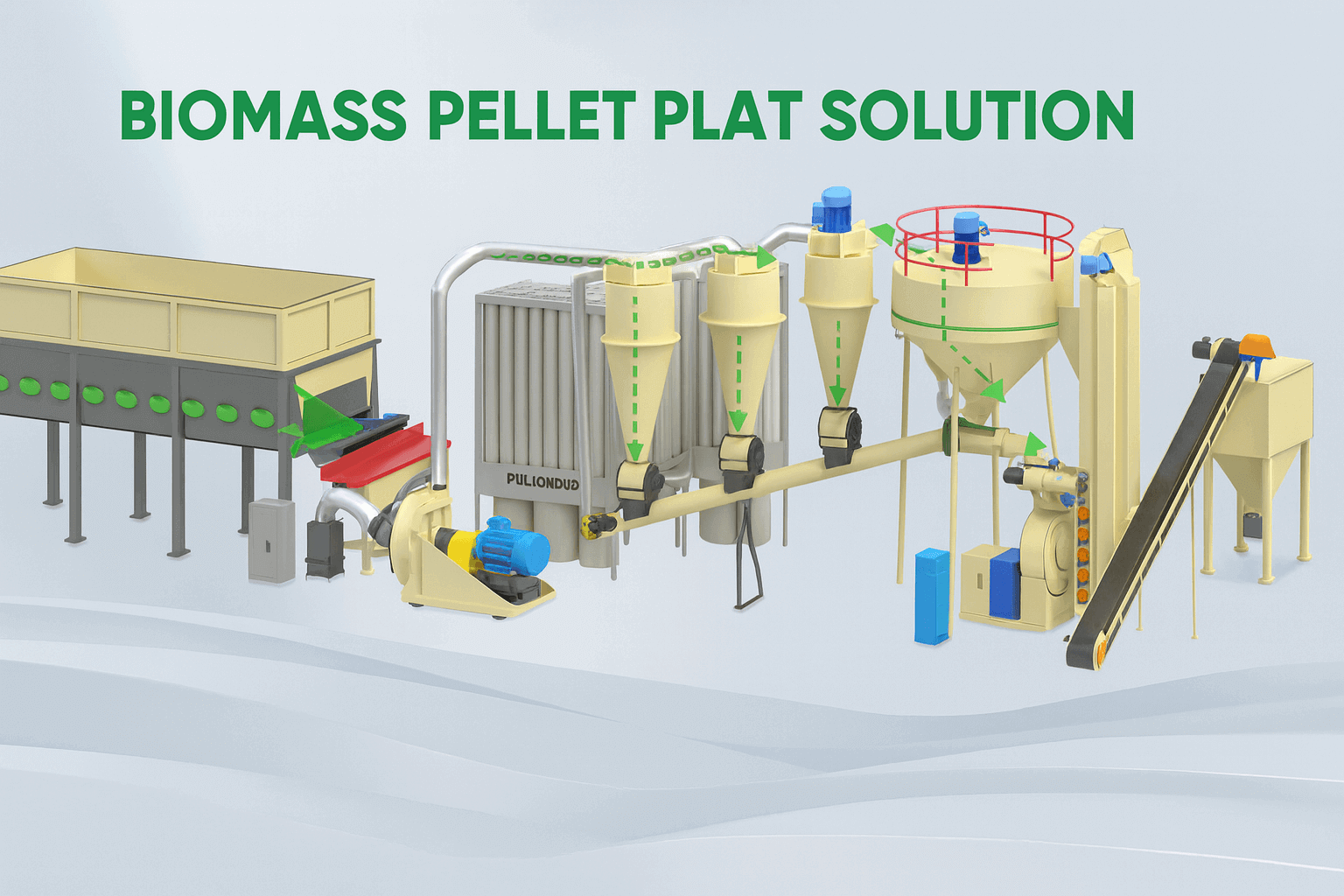

Complete Pellet Plant Solutions

We don't just supply machines - we deliver fully integrated pellet manufacturing plants.

From raw material preparation to finished pellet packaging, we provide complete, turnkey solutions that include:

Everything is engineered to work as one efficient and reliable production line.

Experience You Can Trust

Our manufacturing partner brings over 70 years of expertise in pellet production technology. Their equipment is recognised globally for durability, precision, and consistent performance.

Wide Range of Materials We Can Process

Our pellet lines are designed to handle multiple types of biomass and bulk materials, such as:

We tailor each plant to your local raw materials and production requirements.

Why Biomass Pellets?

Global Reach & Trusted Export Expertise

We proudly serve clients across Asia, Africa, Europe, and the Americas.

Our extensive export experience ensures:

Why Choose Us

Looking to Build or Expand a Pellet Production Facility?

Whether you want a compact line or a full-scale industrial manufacturing plant, we can design the right solution for you.

Share your project details, and we'll prepare a tailored, complete pellet plant proposal.

Get Your Custom Proposal